In company workshop Root Cause Analysis

At first glance Root Cause Analysis appears to be simplicity itself. The results are logical and easy to understand. This makes the method powerful. But getting good results is not a trick but a mindset.

To perform effective Root Cause Analysis requires a different way of looking at and thinking about incidents and quality problems. The Hadrion training is designed to accomplish this mindset. From start to finish the participants are confronted with several (real) safety or quality incidents. They immediately have to apply the theory. They learn and adapt on the spot. The training is no place for idly listening.

Participants will also analyze an incident from their own work environment.

What does the training look like?

The training consists of two consecutive days. Day 1 has a morning and afternoon session of theory and practice. The morning session of day 2 lets the participants apply RCA to an incident from their own location. The afternoon session of day 2 is used to extend and expand their RCA skill.

Day 1

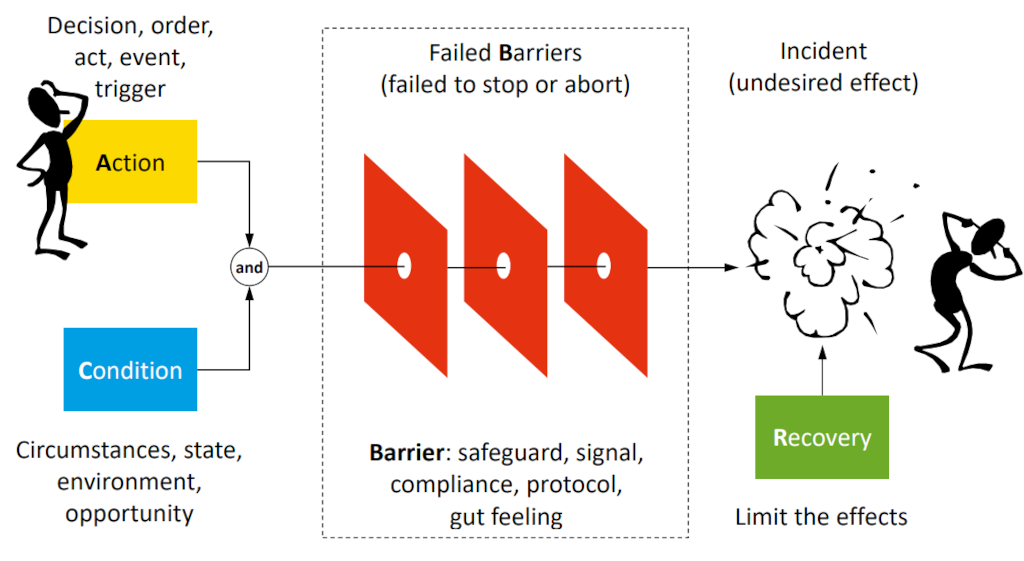

The first training day is focused on the main tools of an RCA. In advance the participants receive a case with a set of questions. Participants learn to identify ABC-causes. They learn how to start exploring a problem with their team and uncover relevant questions. They learn to visualise all causalities in a cause tree, to make the problem clear and pave the way for effective solutions.

- Root Cause Analysis

- The anatomy of quality problems and incidents

- Creating a time line

- Cause tree analysis

- Investigating and interviewing

- Wrap up...

Day 2

During the morning session the participants can practice applying RCA to an incident that recently happened at their own location or company. The trainer is available for questions and support. The morning session closes as the participants present their results. The afternoon session is designed to extend and expand on practical RCA application.

- Brief brush up

- Problem definition

- Participants apply RCA to their own case

- Classification of Root Causes

- Adding proof to a cause tree

- Introduction to Human Factors

- Evaluation and finishing remarks

Results

The participants learn how to recognize the important elements that make up an incident or quality problem. They learn how to define, investigate, interview and analyze. They learn how to look beyond the direct causes to find the root causes of an incident or quality problem. They learn how to use the RCA tools to persuade key people (e.g. management) to implement improvement measures that work.

A training at your location?

Contact us to explore the possibilities of a training at your location?

Language

The language spoken during the training is English (or Dutch).

Reference materials can be provided in Dutch, English, French, German and more...

Participants

Participants work in the industry, service sector or health care. They are involved in evaluating safety incidents, quality problem and/or complaints.

The maximum number of participants is 14.

Time investment:

De workshop consists of two days of 7 hours each.

Each participants spends 14 hours attending the training and 2 hours on preparation.

Price:

Fixed price includes: intake, travel, training, course materials and access to extra on-line materials.

Location

The training room influences the effect of the training. The following is required:

- Ample space to let the participants work in groups of 2 to 4 people (40-50 m2).

- Well ventilated room.

- Projector and projection screen or large TV.

- Enough room to hang flip-over papers on walls and windows.

- Coffee, tea, water available.

- Lunch location at walking distance

What participants say?

Participants say the following about the training:

“Very practical. Lots of practice.”,

“Very usefull. Learned a lot”,

“Time flies”,

“Actually fun to do”,

“Very practical tools!",

"If you know how to do it, you can start immediately”.